Vapor Barrier

Vapor Barrier 10mil

Products

| Roll Size (sq. ft.) |

Vapor Classification | Width | Length | Type | SKU | Weight (lbs) |

|---|---|---|---|---|---|---|

| 1200 | Class A | 12' | 100' | VB | VP-1200-10BW | 48.5 lbs/roll |

Vapor Barrier 12mil

Products

| Roll Size (sq. ft.) |

Vapor Classification | Width | Length | Type | SKU | Weight (lbs) |

|---|---|---|---|---|---|---|

| 1200 | Class A | 12' | 100' | VB | VP-1200-12WW | 56 lbs/roll |

Vapor Barrier 14mil

Products

| Roll Size (sq. ft.) |

Vapor Classification | Width | Length | Type | SKU | Weight (lbs) |

|---|---|---|---|---|---|---|

| 1200 | Class A | 12' | 100' | VB | VP-1200-14WW | 68.5 lbs/roll |

Vapor Barrier 16mil

Products

| Roll Size (sq. ft.) |

Vapor Classification | Width | Length | Type | SKU | Weight (lbs) |

|---|---|---|---|---|---|---|

| 1200 | Class A | 12' | 100' | VB | VP-1200-16WW | 78 lbs/roll |

Vapor Barrier 20mil

Products

| Roll Size (sq. ft.) |

Vapor Classification | Width | Length | Type | SKU | Weight (lbs) |

|---|---|---|---|---|---|---|

| 1200 | Class A | 12' | 100' | VB | VP-1200-20WW | 96 lbs/roll |

The use of vapor barriers is crucial and often required in various construction and building applications. Class A vapor barriers are specifically designed to prevent moisture penetration from the ground through concrete slabs and to protect crawl spaces from moisture infiltration. VaporShiels’ vapor barrier solutions include a range of durable options, from 10 mil to 20 mil thickness, engineered for exceptional effectiveness and long-lasting performance.

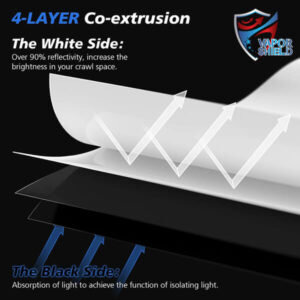

VaporShield products are crafted with a heavy-duty, high-density reinforced core and a smooth finish, ensuring superior durability, strength, puncture resistance, and seamless overlapping to effectively minimize moisture leaks

VaporShield Barriers provide a low permeance rating, effectively reducing the risk of water vapor buildup and the infiltration of soil gases. This ensures the durability of the building envelope and supports better indoor air quality by preventing significant moisture-related problems.

APPLICABLE STANDARDS (ASTM):

ASTM E1745 sets the standard for flexible sheet membranes used as vapor retarders in on-ground and below-grade slab applications beneath concrete. The standard requires products to undergo testing for tensile strength, puncture resistance, and water vapor

permeance. This permeance is assessed both before and after the mandatory conditioning tests to ensure reliability and performance.

ASTM E1745: Standard Specification for Water Vapor Retarders Used in Contact with Soil or Granular Fill Under Concrete Slabs

- ASTM F1249: Test Method for Water Vapor Transmission Rate through Plastic Film and Sheeting using a Modulated Infrared Sensor

- ASTM D1709: Test Methods for Impact Resistance of Plastic Film by Free-Falling Dart Method

- ASTM D882: Test Method for Tensile Properties of Thin Plastic Sheeting

- ASTM E154: Standard Test Methods for Water Vapor Retarders used in Contact with Earth under Concrete Slabs, on Walls, or as Ground Cover

Application Example:

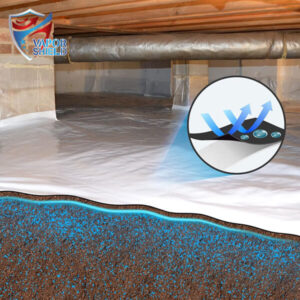

VaporShield Class A Vapor Barrier in CrawlSpace (encapsulation):

Benefits of Using a Class A Vapor Barrier in a Crawl Space

Installing a Class A vapor barrier in a crawl space provides numerous advantages that improve structural integrity, energy efficiency, and overall comfort in a building. Here are the key benefits:

1. Moisture Control

- Prevents Ground Moisture: Stops water vapor from rising into the crawl space, reducing humidity levels.

- Protects Against Condensation: Minimizes the risk of condensation on wood and other surfaces, preventing damage.

2. Reduces Radon Migration:

VaporShield barriers are high-performance vapor barriers crafted from premium virgin polyolefin resin, featuring a low radon diffusion coefficient. They are an excellent component of your ASD (Active Soil Depressurization) system, effectively minimizing radon infiltration into homes and enhancing indoor air quality.

3. Mold and Mildew Prevention

- Limits Growth: By controlling humidity, it inhibits the growth of mold and mildew, which can cause health issues and damage materials.

- Improves Air Quality: Reduces the spread of allergens and contaminants into living spaces.

4. Structural Protection

- Prevents Wood Rot: Protects wooden beams, joists, and subflooring from moisture-related decay.

- Stops Corrosion: Reduces the risk of rust and corrosion on metal components in the crawl space.

5. Energy Efficiency

- Enhances Insulation Performance: A dry crawl space improves the effectiveness of insulation, reducing heating and cooling costs.

- Minimizes HVAC Strain: Helps maintain consistent indoor temperatures, reducing strain on HVAC systems.

6. Pest Deterrence

- Discourages Infestation: Eliminates moisture that attracts pests like termites, ants, and rodents.

7. Longevity of Materials

- Extends Lifespan: Ensures that structural and mechanical components last longer by reducing exposure to moisture and humidity.

8. Compliance with Building Codes

- Meets Standards: Class A vapor barriers often meet stringent building codes for flame resistance and moisture control, ensuring compliance with safety regulations.

9. Increases Home Value

- Improved Market Appeal: A well-maintained crawl space with a vapor barrier increases the resale value of a property by demonstrating proactive maintenance.

10. Health and Comfort

- Improved Indoor Environment: Reduces the risk of musty odors and airborne mold spores, creating a healthier living space.

Thermal Comfort: Helps maintain a consistent indoor temperature, enhancing comfort year-round.

Installing a Class A vapor barrier is a critical investment for homeowners and property managers seeking to protect their crawl space and ensure a healthy, energy-efficient, and durable structure.

Installation Idea: